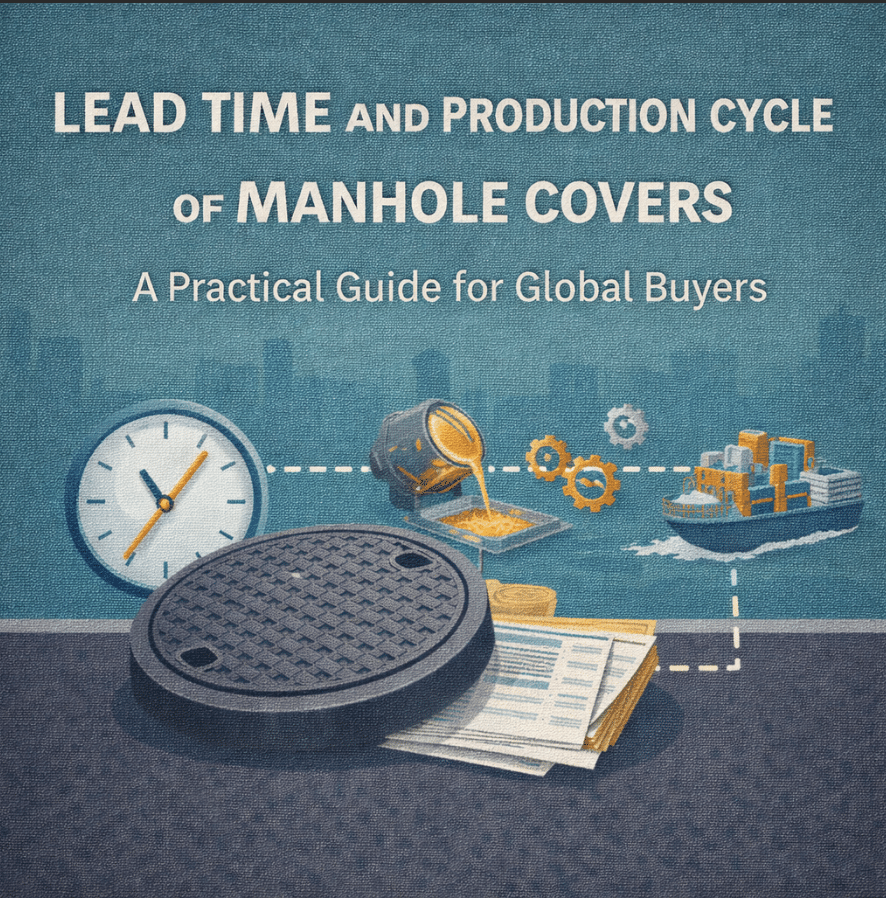

In infrastructure projects, few components appear as simple yet prove as critical as manhole covers. While design standards and load-bearing performance often receive the most attention, lead time and production cycle of manhole covers play an equally decisive role in project success. Delays in manhole cover delivery can disrupt construction schedules, increase labor costs, and even cause contractual penalties—especially in municipal, road, and utility projects.

1. What Is Lead Time in Manhole Cover Manufacturing?

Lead time in manhole cover manufacturing refers to the total period from order confirmation to product readiness for shipment. It is not a single-stage metric but a combination of multiple interconnected processes, each contributing to the final delivery schedule. For cast iron and ductile iron manhole covers, lead time typically ranges from 15 to 45 days, depending on order complexity and production capacity.

The lead time of manhole covers usually includes design confirmation, mold preparation, casting, machining, surface treatment, quality inspection, and packaging. Any changes in specifications—such as load class upgrades, customized logos, or anti-theft features—can extend this cycle. Buyers who understand how lead time is structured can better align procurement schedules with construction milestones and avoid unnecessary project delays.

2. Overview of the Manhole Cover Production Cycle

The manhole cover production cycle is a systematic industrial process designed to ensure strength, durability, and compliance with international standards such as EN124 or ASTM. It begins with raw material preparation and ends with shipment-ready products. Unlike mass-produced consumer goods, manhole covers often require project-specific adjustments, which directly affect production duration.

A standard production cycle includes material melting, casting, cooling, surface finishing, dimensional machining, and performance testing. Each step must be completed sequentially and verified for quality. Understanding this cycle allows buyers to evaluate whether a manufacturer’s promised delivery time is realistic or overly optimistic. Reliable suppliers clearly communicate each phase of the production cycle and provide transparent scheduling updates throughout the manufacturing process.

3. Key Stages That Affect Lead Time of Manhole Covers

Several critical stages directly influence the lead time of manhole covers. The first is mold preparation. If standard molds are available, production can begin quickly. However, custom manhole covers often require new molds, which may add 5–10 days to the timeline.

Casting and cooling are another time-sensitive stage. Ductile iron requires controlled cooling to achieve optimal mechanical properties, which cannot be rushed without compromising quality. Surface treatments such as bitumen coating, epoxy coating, or hot-dip galvanizing also extend the production cycle. Finally, quality inspection and load testing—essential for international projects—require additional time but are crucial for long-term safety and compliance.

4. Standard vs Custom Orders: Lead Time Differences

One of the most common misunderstandings in procurement is assuming all manhole covers share the same production timeline. In reality, standard manhole covers typically have shorter lead times because molds, patterns, and test procedures already exist. These orders can often be completed within two to three weeks.

Custom manhole covers, on the other hand, involve design validation, mold fabrication, and sometimes third-party certification. These steps significantly extend the production cycle, often to four to six weeks. Buyers requesting customized logos, special dimensions, or non-standard load classes should plan accordingly. Understanding this distinction helps project managers balance customization needs with construction deadlines.

5. How Manufacturers Optimize Production Cycles

Experienced manhole cover manufacturers invest heavily in optimizing their production cycles to reduce lead time without sacrificing quality. This includes maintaining an inventory of commonly used molds, automating casting lines, and integrating in-house machining and coating facilities. Such vertical integration allows suppliers to control scheduling more effectively.

Advanced production planning systems also play a role. By forecasting demand and batching similar orders, manufacturers can shorten turnaround times. For buyers, choosing a supplier with proven production efficiency means not only faster delivery but also greater reliability. Evaluating a manufacturer’s production capacity and past delivery performance is essential when lead time is a critical factor.

6. International Shipping and Its Impact on Delivery Time

While production is a major component, international shipping is another factor that affects the overall delivery schedule. Even if the manhole cover production cycle is efficient, poor logistics planning can negate these advantages. Sea freight, customs clearance, and port congestion must be factored into the total lead time.

Buyers should distinguish between factory lead time and door-to-door delivery time. A transparent supplier clearly separates production duration from shipping schedules and provides realistic estimates. Proper packaging, accurate documentation, and compliance with export regulations further ensure that manhole covers arrive on site without delays or damage.

Conclusion

The lead time and production cycle of manhole covers are not merely logistical details—they are strategic considerations that directly impact project timelines and costs. By understanding how manhole covers are manufactured, what factors extend production cycles, and how suppliers manage lead time, buyers can make smarter sourcing decisions.

Selecting a manufacturer with transparent processes, adequate capacity, and proven experience reduces risks and enhances project efficiency. Whether ordering standard or custom manhole covers, informed planning and clear communication remain the keys to timely delivery and long-term infrastructure success.

FAQ: Lead Time and Production Cycle of Manhole Covers

1. What is the average lead time for manhole covers?

Typically 15–45 days, depending on whether the order is standard or customized.

2. Do custom manhole covers take longer to produce?

Yes. Custom designs require additional mold preparation and testing, extending the production cycle.

3. Can lead time be shortened without compromising quality?

Only through efficient production planning and automation, not by skipping essential quality steps.

4. Does surface coating affect production time?

Yes. Processes like epoxy or galvanizing add several days to the cycle.

5. How should buyers plan for international delivery?

By separating factory lead time from shipping time and confirming logistics details in advance.