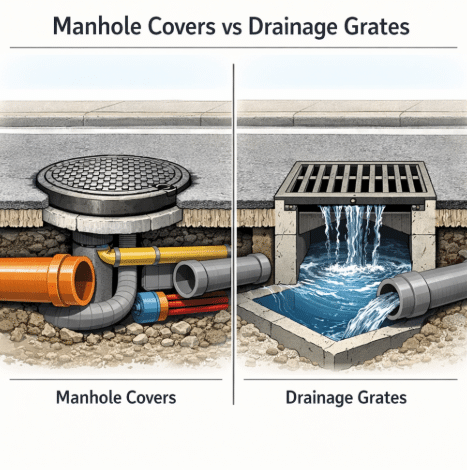

In modern urban infrastructure, manhole covers and drainage grates are two critical surface components that are often mistaken for one another. Although they may appear similar at street level, their functions, structural designs, and performance requirements differ significantly. Understanding the difference between manhole covers and drainage grates is essential for city planners, civil engineers, contractors, and infrastructure buyers who must select the correct product for safety, durability, and regulatory compliance. This article provides an in-depth comparison of manhole covers and drainage grates, examining their purposes, materials, load capacities, standards, and applications across modern cities.

What Is a Manhole Cover?

A manhole cover is a solid or semi-solid cover designed to seal access points to underground utility systems such as sewage networks, stormwater systems, electrical conduits, and telecommunications infrastructure. Its primary purpose is to provide safe, secure access for inspection and maintenance while preventing accidental entry, unauthorized access, or environmental contamination. Manhole covers are typically circular or square and are manufactured from materials such as ductile iron, cast iron, or composite materials. Their design prioritizes structural strength, load-bearing capacity, and long-term durability under heavy traffic conditions.

What Is a Drainage Grate?

A drainage grate is an open or slotted surface component installed over drainage channels, catch basins, or stormwater inlets. Its primary function is to allow surface water to flow efficiently into the drainage system while preventing large debris from entering and causing blockages. Unlike manhole covers, drainage grates are intentionally perforated and optimized for hydraulic performance rather than full enclosure. They are commonly used along roadsides, parking areas, pedestrian zones, industrial yards, and urban landscapes where water management is critical to preventing flooding and surface damage.

Functional Differences Between Manhole Covers and Drainage Grates

The most fundamental difference between manhole covers and drainage grates lies in their function. Manhole covers focus on access and protection, acting as a sealed barrier between the surface environment and underground utilities. Drainage grates, by contrast, are designed for water intake and flow control. While a manhole cover minimizes openings to enhance safety and containment, a drainage grate maximizes openings to ensure efficient water capture. Selecting the wrong component can lead to serious consequences, such as water accumulation, structural failure, or safety hazards for pedestrians and vehicles.

Design and Structural Characteristics

Manhole covers are generally thicker, heavier, and structurally reinforced to withstand static and dynamic loads from vehicles, including heavy trucks. Circular designs are common because they prevent the cover from falling into the opening and distribute stress evenly. Drainage grates, on the other hand, are engineered with slots or grid patterns that balance water flow capacity with surface safety. Their structural design must prevent heel entrapment, bicycle wheel hazards, and excessive deformation under load while maintaining sufficient open area for drainage performance.

Materials Used in Manufacturing

Both manhole covers and drainage grates are manufactured using materials selected for strength, corrosion resistance, and lifespan. Cast iron and ductile iron remain industry standards due to their high load capacity and durability. In recent years, composite materials and reinforced concrete have gained popularity, particularly for drainage grates in corrosive environments or pedestrian areas. However, manhole covers typically require higher material density and thickness to meet safety and access requirements, making their material specifications more demanding than those of drainage grates.

Load Ratings and Standards

Manhole covers and drainage grates are classified according to load ratings defined by international standards such as EN 124. These classifications determine where each product can be safely installed. Manhole covers often fall into higher load classes suitable for highways, industrial zones, and ports. Drainage grates may also be load-rated but are often optimized for specific surface conditions, such as sidewalks or light-traffic areas. Compliance with these standards ensures long-term performance, legal conformity, and public safety.

Installation and Maintenance Considerations

Installation methods for manhole covers and drainage grates differ due to their functions and structural roles. Manhole covers require precise seating and frame alignment to ensure stability and noise reduction under traffic. Drainage grates must be installed with proper slope and alignment to maintain efficient water flow. Maintenance requirements also vary: manhole covers are accessed periodically for inspections, while drainage grates require more frequent cleaning to prevent debris buildup that could reduce drainage efficiency.

Safety Implications in Urban Environments

Safety is a key consideration when comparing manhole covers and drainage grates. Manhole covers must prevent unauthorized access and accidental displacement, while drainage grates must ensure slip resistance and minimize trip hazards. Improper selection or installation can result in accidents, liability risks, and infrastructure damage. Modern designs increasingly incorporate anti-slip textures, locking mechanisms, and noise-reduction features to enhance safety and usability in dense urban settings.

Applications in Modern Cities

In contemporary cities, manhole covers and drainage grates are strategically deployed based on functional requirements. Manhole covers dominate roadways, intersections, and utility corridors where underground access is essential. Drainage grates are concentrated in areas prone to surface water accumulation, such as curbs, plazas, and industrial zones. Understanding their distinct roles allows municipalities and developers to design more resilient, efficient, and safer urban infrastructure systems.

Conclusion

The difference between manhole covers and drainage grates extends far beyond appearance. Each serves a distinct and indispensable role in urban infrastructure, with unique functional, structural, and safety requirements. Manhole covers prioritize secure access and load resistance, while drainage grates focus on water management and surface safety. Selecting the appropriate component based on application, load conditions, and regulatory standards is essential for long-term performance and public safety. As cities continue to evolve, a clear understanding of these differences supports smarter infrastructure planning and investment.

Frequently Asked Questions (FAQ)

1. Can drainage grates replace manhole covers?

No. Drainage grates cannot provide the sealed access and structural protection required for underground utility chambers.

2. Are manhole covers always solid?

Most are solid, but some include ventilation holes depending on application and safety requirements.

3. Which one requires higher load capacity?

Manhole covers generally require higher load ratings, especially in traffic and industrial areas.

4. Do drainage grates require more maintenance?

Yes. They require regular cleaning to maintain effective water flow and prevent blockages.

5. Are both products regulated by the same standards?

They often fall under the same standards, such as EN 124, but are classified differently based on function and load.