Manhole covers are common objects found in cities and towns. Even though we often ignore them, they play a vital role in our underground systems. They help keep our sewage, drainage, and telecommunications running well. Manhole covers are built using casting processes to last and provide access to the opening of a manhole for workers who need to maintain, repair, and monitor these systems. This guide will help you learn about manhole covers. You will discover the different types, their benefits, and important things to think about when you need to buy one.

Types of Manhole Covers

Manhole covers come in many different materials, each with its pros and cons. The two most common types are cast iron and composite.

Cast iron and ductile iron have been popular choices for cast iron manhole frames and covers for many years. Ductile iron is very strong and durable. These covers can handle a lot of weight, so they are great for busy areas. In contrast, composite manhole covers are usually made from materials like fiberglass and resin. They are lighter and have benefits such as not rusting easily and being safer.

Advantages and Disadvantages of Cast Iron Covers

Cast iron manhole covers are often the best choice in the industry. Their strong build is great for busy traffic areas and gives good access to sewer systems.

Cast iron is known for its toughness and lasts a long time. It can handle heavy loads and tough weather. This makes it a smart financial choice, even though it costs more at first because it lasts longer.

But there are a few downsides to cast iron covers. They are heavy, which can make them hard to install or remove, sometimes needing special tools. Also, they can rust and corrode over time, especially in places with road salt and harsh chemicals.

Innovations in Composite Manhole Covers

Composite manhole covers have come up as a lighter and stronger choice, due to the problems with traditional materials. Made from strong materials like fiberglass and resin, these covers offer many benefits over cast iron ones.

First, their lighter weight makes them easy to handle and install. This means there is no need for heavy machines. It also lowers the chances of injuries when putting them in or taking them out. Additionally, composite covers do not rust or corrode, which helps them last longer and need less maintenance.

Besides these main benefits, composite manhole covers have introduced some great new features. These include:

- Integrated locks to improve security and prevent theft and unauthorized access.

- Sensors and monitoring technology built into the covers. This allows for real-time data on things like temperature, gas levels, and flow rates. This helps in better managing infrastructure.

Key Considerations When Choosing Manhole Covers

Choosing the right manhole cover needs careful thought. You must consider several factors to find what works best for you. The use and location are very important in deciding what type of cover to choose.

For example, in busy areas, you need a round manhole cover that can hold more weight. Also, think about the weather. Places with lots of rain or near the ocean need covers made of materials that resist rust and can be securely locked in place with a quarter turn. By factoring in these points, you can find a manhole cover that is strong and fits your needs.

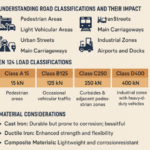

Load Rating – Understanding the Basics

One important thing to think about when choosing a manhole cover is its load rating. This is measured in kilograms or pounds. The load rating tells you the most weight a manhole cover can hold before it fails. Choosing the right load rating is very important to keep pedestrians and vehicles safe.

Load ratings come in different classes, usually from A to F. Class A is okay for pedestrian areas, while Class F can handle really heavy loads like planes. When picking a cover, think about how much traffic is expected. Areas with heavy trucks need covers with higher load ratings than places used only by people walking.

Check local building codes or speak with a qualified engineer. This can help you find the right load rating for your area and what you need.

Material Durability and Longevity

The material used in a manhole cover plays a big role in how long it lasts. Manhole covers face tough conditions like heavy traffic, changing temperatures, and contact with sewage and harsh chemicals. Choosing the right material is important for lasting performance.

Cast iron covers are popular because they are strong and durable. However, composite materials are becoming a strong choice too. Composite covers resist corrosion, chemicals, and UV light well. This means they can last longer and need less upkeep.

In the end, the best material choice depends on a few things, like your budget, how long you need it to last, and the specific environment where it will be used. By looking closely at these factors, you can choose a material that provides good durability without spending too much.

Installation and Maintenance Tips

A well-installed manhole cover is important for both safety and usefulness. Regular care is also key to help it last longer and work better.

It’s very important to follow the manufacturer’s instructions when installing. Make sure the manhole frame is level with the pavement. This will stop tripping risks and uneven weight. Using a sealant or gasket around the edges of the cover helps it fit tightly. This keeps out dirt and water and reduces noise from traffic.

Proper Installation Techniques for Safety

Proper installation of manhole covers is very important for keeping both people and vehicles safe. A well-fitted cover stops it from moving out of place and makes sure it is stable even under heavy weight.

To start, check that the manhole frame is at the same level as the pavement. You can use a spirit level for this. If the base material is not right, adjust it as needed. Any bumps or hollows can cause problems and make it unsafe.

After leveling the frame, gently lower the cover into place. Make sure it is even with the frame. Do not drop the cover, as this can harm both the cover and the frame. Once the cover is in place, look around the frame to make sure it blends well with the pavement.

Maintenance Best Practices to Extend Lifespan

Regular maintenance practices play a crucial role in extending the lifespan of your manhole covers and access covers, ensuring their continued functionality and safety. While seemingly straightforward, neglecting maintenance can lead to costly repairs and premature replacement.

Periodically inspect covers for signs of wear and tear, including cracks, chips, or corrosion. Promptly address any identified issues to prevent further damage. Keep the cover and frame clear of debris and dirt, which can hinder proper sealing and lead to water infiltration or unpleasant odors.

Below is a table outlining a simple yet effective maintenance schedule:

| Task | Frequency |

| Visual inspection for damage & debris | Monthly |

| Clean cover and frame | Quarterly |

| Check and tighten or replace bolts and seals | Annually |

Conclusion

Investing in the right manhole cover is very important for durability and safety in the long run. You can choose either cast iron covers or other new composite options. It is essential to know about load ratings and how durable the materials are. Using the correct installation methods and keeping up with maintenance can help manhole covers last longer. If you think about these tips, you can make sure your manhole covers stay reliable and last a while. If you have more questions or need help picking the best manhole cover, you can check our FAQ section or contact us for expert advice.

Frequently Asked Questions

What is the most durable material for manhole covers?

Both cast iron and composite materials are very strong for manhole covers. Cast iron is well-known for its strength and ability to hold weight. On the other hand, composite materials are great at resisting corrosion and are lighter. This lighter weight makes them easier to manage when installing and maintaining the manhole opening.

How do I choose the right load rating for my needs?

Choosing the right load rating is important. It depends on what kind of traffic you expect. Think about the weight and size of the vehicles that will drive over the manhole cover. You can look at load rating charts. These charts usually group ratings based on the type of traffic. They can help you pick the right option.

What materials are commonly used to make manhole covers?

Manhole covers are commonly made from materials like cast iron, ductile iron, and composite materials such as fiberglass. Each material offers different benefits in terms of durability, weight, and resistance to corrosion, allowing for a wide range of options to suit various applications.