Manhole covers are integral to urban infrastructure, providing access to underground utilities while ensuring the safety of pedestrians and vehicles. Their performance requirements vary significantly based on road classifications, necessitating adherence to specific standards and material considerations.

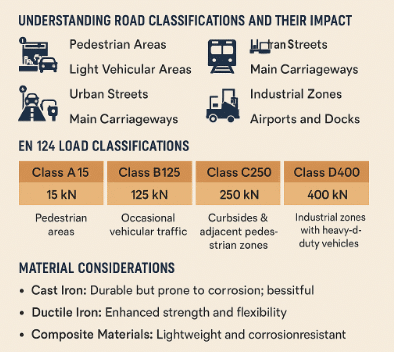

Understanding Road Classifications and Their Impact

Roads are categorized based on their usage and traffic load, influencing the specifications for manhole covers:

- Pedestrian Areas (Group 1): Zones with foot traffic only.

- Light Vehicular Areas (Group 2): Driveways and parking areas with occasional vehicle access.

- Urban Streets (Group 3): Areas with slow-moving traffic, including sidewalks adjacent to roads.

- Main Carriageways (Group 4): Primary roads with regular vehicular traffic.

- Industrial Zones (Group 5): Areas with heavy-duty vehicles, such as loading docks.

- Airports and Docks (Group 6): Zones subjected to extremely high wheel loads.

Each classification dictates the load-bearing requirements for manhole covers installed within them.

EN 124 Load Classifications

The EN 124 standard outlines six primary load classes for manhole covers:

- Class A15 (15 kN): Suitable for pedestrian areas.

- Class B125 (125 kN): Designed for areas with occasional vehicular traffic.

- Class C250 (250 kN): Applicable to curbsides and pedestrian zones adjacent to roads.

- Class D400 (400 kN): Ideal for main carriageways and roads with heavy traffic.

- Class E600 (600 kN): Meant for industrial zones with heavy-duty vehicles.

- Class F900 (900 kN): Reserved for airports and docks with extremely high wheel loads.

Selecting the appropriate class ensures the manhole cover can withstand the expected loads without failure.

Material Considerations

The choice of material significantly affects the performance and longevity of manhole covers:

- Cast Iron: Traditional material offering durability; suitable for various load classes but prone to corrosion.

- Ductile Iron: Provides enhanced strength and flexibility, making it ideal for higher load classes.

- Composite Materials: Lightweight and corrosion-resistant; best for areas with lower load requirements.

Material selection should align with the specific demands of the road classification and environmental conditions.

Design and Safety Features

Beyond material and load capacity, design features contribute to the safety and functionality of manhole covers:

- Anti-Skid Surfaces: Textured designs prevent slips, especially in wet conditions.

- Secure Fittings: Proper seating and locking mechanisms prevent displacement under traffic loads.

- Corrosion Resistance: Protective coatings extend the lifespan, particularly in corrosive environments.

Incorporating these features ensures the manhole cover remains safe and operational throughout its service life.

Compliance with Standards

Adherence to established standards guarantees the reliability of manhole covers:

- BS EN 124: Defines load classes and installation areas.

- ASTM F1143/F1144: Specifies design and construction criteria for manhole cover assemblies.

- ISO 15398: Outlines requirements for thermoplastic covers in non-traffic areas.

Compliance ensures that manhole covers meet the necessary safety and performance benchmarks.

Conclusion

Manhole covers must be tailored to the specific demands of their installation environment. By understanding road classifications, adhering to load standards, selecting appropriate materials, and incorporating essential design features, engineers can ensure the safety and durability of these critical infrastructure components.

FAQs

Q: How do I determine the appropriate load class for a manhole cover?

A: Assess the road classification where the cover will be installed and refer to the EN 124 standard to select the corresponding load class.

Q: Are composite manhole covers suitable for high-traffic areas?

A: Generally, composite covers are best for low to medium traffic areas due to their lightweight nature. For high-traffic zones, ductile iron is recommended.

Q: What maintenance is required for manhole covers?

A: Regular inspections for wear, corrosion, and secure fitting are essential. Prompt replacement or repair ensures continued safety.

Q: Where can I source high-quality manhole covers at competitive prices?

A: Manufacturers like Xinghua Casting offer durable and cost-effective manhole covers that comply with international standards.

Q: Do all D400 manhole covers meet highway requirements?

A: Not necessarily. While D400 covers are designed for roads, it’s crucial to verify that they meet specific national standards, such as CD 534 in the UK, to ensure suitability for particular highway conditions.