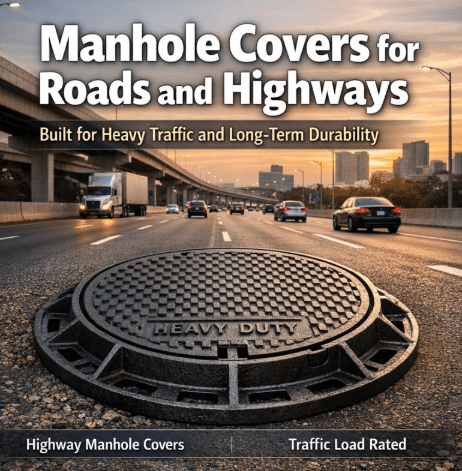

Manhole covers for urban roads and highways are a critical yet often underestimated component of modern transportation infrastructure. They serve as the protective interface between underground utility networks—such as drainage, sewage, telecommunications, and power systems—and the constant mechanical stress generated by surface traffic. As cities expand and vehicle volumes increase, the performance requirements for road and highway manhole covers continue to rise.

Poorly designed or inadequately installed manhole covers can lead to road surface failures, traffic accidents, noise pollution, and costly maintenance cycles. For this reason, manhole covers for urban roads and highways must meet strict standards for load-bearing capacity, durability, stability, and safety.

The Role of Manhole Covers in Urban Road and Highway Infrastructure

In urban road and highway systems, manhole covers play a dual role: protecting underground utilities while maintaining the continuity and safety of the road surface. These covers must withstand constant dynamic loads from cars, buses, trucks, and heavy commercial vehicles, often under high-speed conditions. Any failure can disrupt traffic flow and compromise public safety.

Unlike pedestrian-area covers, road and highway manhole covers are exposed to repetitive impact loads, vibration, braking forces, and temperature fluctuations. They must remain securely seated within their frames to prevent displacement, rattling, or subsidence. In addition, they are often located in critical traffic lanes, making accessibility for maintenance without major road closures an important design consideration. A well-integrated manhole cover system contributes directly to smoother traffic operations and longer pavement life.

Load-Bearing Requirements and Traffic Classification

One of the most important performance indicators for manhole covers used on urban roads and highways is load-bearing capacity. International standards such as EN 124 classify manhole covers into load classes based on expected traffic conditions, ranging from light pedestrian use to heavy-duty highway applications.

For highways and major urban roads, covers typically fall into high load classes designed to withstand extreme axle loads and frequent traffic cycles. Heavy-duty manhole covers must distribute loads evenly across the frame and surrounding pavement structure to avoid localized stress concentrations. Engineers also consider factors such as vehicle speed, traffic density, and braking zones when selecting the appropriate cover design.

Choosing the correct load classification is essential not only for safety but also for long-term cost control, as under-rated covers can lead to premature failure and repeated repairs.

Material Selection for Road and Highway Manhole Covers

Material choice has a significant impact on the performance and lifespan of manhole covers for urban roads and highways. Common materials include ductile iron, cast iron, steel, and composite materials. Among these, ductile iron is widely regarded as the most reliable option for high-traffic environments due to its superior mechanical properties.

Ductile iron offers high tensile strength, excellent fatigue resistance, and improved impact absorption compared to traditional cast iron. This makes it particularly suitable for areas subjected to heavy traffic and dynamic loading. Steel covers, while strong, may require additional corrosion protection, while composite covers are often limited to lighter traffic applications.

Selecting the right material involves balancing structural performance, environmental conditions, lifecycle cost, and compliance with local regulations.

Safety Design and Anti-Displacement Features

Safety is a top priority for manhole covers installed on urban roads and highways. A displaced or broken cover can pose serious risks to vehicles and pedestrians alike. To mitigate these risks, modern manhole cover designs incorporate anti-displacement and anti-tilting features.

These may include precision-machined frames, locking mechanisms, or hinged designs that prevent unauthorized opening. Anti-slip surface patterns are also commonly applied to improve tire grip, especially during wet or icy conditions. Noise reduction is another important safety-related factor, as loose or poorly seated covers can create distracting sounds that affect driver concentration.

Well-designed safety features help ensure that manhole covers remain stable and functional throughout their service life, even under demanding traffic conditions.

Installation Quality and Road Integration

Even the highest-quality manhole cover can fail if it is improperly installed. Installation quality is therefore a critical factor in the performance of manhole covers for urban roads and highways. Proper alignment, frame seating, and integration with the surrounding pavement structure are essential to prevent settlement and uneven surfaces.

Installation practices must account for road materials, subgrade conditions, and expected traffic loads. In highway environments, where maintenance access can be disruptive, precise installation helps minimize future interventions. Modern installation techniques also focus on reducing vibration transmission and extending the lifespan of both the cover and the surrounding road surface.

Effective coordination between designers, contractors, and municipal authorities is key to achieving consistent installation quality.

Long-Term Maintenance and Lifecycle Performance

Lifecycle performance is a major consideration for municipalities and road authorities managing extensive infrastructure networks. Manhole covers for urban roads and highways are expected to perform reliably for decades with minimal maintenance. Durable materials, proper installation, and thoughtful design all contribute to reduced maintenance frequency.

Routine inspections help identify early signs of wear, frame loosening, or surface damage before they escalate into safety hazards. Compared to lower-grade alternatives, high-quality road manhole covers typically offer lower total cost of ownership by reducing repair cycles, traffic disruptions, and liability risks.

From a long-term planning perspective, investing in robust manhole cover systems supports sustainable infrastructure management and budget predictability.

Conclusion

Manhole covers for urban roads and highways are essential components of safe, efficient, and durable transportation systems. Their performance directly affects road safety, traffic flow, and the longevity of underground utility networks. By carefully considering load-bearing requirements, material selection, safety design, installation quality, and lifecycle performance, stakeholders can ensure that manhole cover systems meet the growing demands of modern urban mobility.

As cities continue to expand and traffic volumes increase, the importance of reliable, well-engineered manhole covers will only grow. Choosing the right solutions today lays the foundation for safer and more resilient road infrastructure in the future.

Frequently Asked Questions (FAQ)

1. What load class is required for manhole covers on highways?

Highways typically require heavy-duty load classes designed for frequent and high axle loads, often specified by international standards such as EN 124.

2. Why is ductile iron commonly used for road manhole covers?

Ductile iron offers high strength, impact resistance, and durability, making it ideal for heavy traffic and long-term use.

3. Can manhole covers cause road accidents?

Yes, poorly designed or installed covers can lead to vehicle instability, noise, or sudden surface irregularities, increasing accident risk.

4. How often should highway manhole covers be inspected?

Regular inspections are recommended, especially in high-traffic areas, to detect wear, loosening, or settlement early.

5. Are anti-slip surfaces important for road manhole covers?

Yes, anti-slip patterns improve tire traction and enhance safety during wet or icy conditions.