Industrial parks and factories operate in environments that demand high levels of safety, durability, and compliance with international standards. Among the many infrastructure components often overlooked, manhole covers for industrial parks and factories play a critical role in ensuring operational safety, protecting underground utilities, and supporting heavy traffic loads from trucks, forklifts, and industrial machinery. Unlike residential or pedestrian areas, industrial facilities expose manhole covers to extreme mechanical stress, chemical exposure, temperature variations, and continuous traffic cycles.

Selecting the wrong type of manhole cover can result in structural failure, production downtime, safety hazards, and costly repairs. Therefore, procurement teams, engineers, and facility managers must understand material options, load classifications, design considerations, and long-term maintenance requirements.

1. Why Industrial Parks and Factories Require Specialized Manhole Covers

Industrial parks differ significantly from residential or commercial zones in terms of load intensity and environmental exposure. Heavy trucks, container carriers, and forklifts frequently pass over drainage and access points, placing enormous stress on manhole covers. As a result, standard light-duty covers are unsuitable and may fail prematurely.

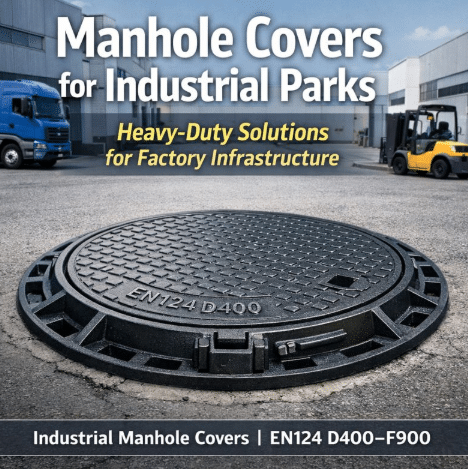

Specialized manhole covers for industrial parks and factories are engineered to withstand high static and dynamic loads, often meeting EN124 D400, E600, or even F900 classifications. These covers are designed with reinforced frames, optimized rib structures, and precise casting tolerances to ensure stability under repeated stress. Additionally, industrial environments often involve oil, chemicals, and corrosive substances, making material selection critical for long-term durability and safety compliance.

2. Common Materials Used for Industrial Manhole Covers

Material choice directly affects performance, lifespan, and maintenance costs. The most widely used materials for industrial applications include ductile iron, cast iron, composite materials, and steel.

Ductile iron manhole covers are the preferred choice for most industrial parks due to their excellent tensile strength, impact resistance, and fatigue performance. They meet stringent international standards and perform reliably under heavy vehicle loads.

Cast iron covers remain popular for certain factory zones but may be less resistant to impact compared to ductile iron. Composite manhole covers, made from fiberglass or polymer materials, offer corrosion resistance and lightweight handling but are generally limited to medium-load industrial areas. Steel covers are sometimes used in customized factory installations but require anti-corrosion treatment and regular maintenance.

3. Load Classification and International Standards

Understanding load classification is essential when selecting manhole covers for industrial parks and factories. International standards such as EN124, AASHTO, and BS standards define load ratings based on installation environments.

For most industrial zones, EN124 D400 (40 tons) is the minimum recommended rating, suitable for roads within industrial parks. Heavy-duty zones such as logistics hubs, ports, or steel plants may require E600 or F900 rated covers. Compliance with these standards ensures not only safety but also legal and insurance acceptance in international projects.

Manufacturers should provide third-party test reports, material certificates, and quality inspection records to support compliance claims. Buyers are advised to verify these documents as part of their procurement process.

4. Design Considerations for Industrial Applications

Beyond material and load capacity, design plays a vital role in performance and usability. Anti-slip surface patterns improve safety for workers and vehicles, especially in wet or oily environments. Tight-fitting frames reduce noise and vibration, contributing to safer and quieter factory operations.

Sealed or gasketed manhole covers help prevent the ingress of water, dust, and chemicals into underground systems. Hinged designs or locking mechanisms enhance security and reduce the risk of unauthorized access. In modern industrial parks, customized designs with logos, color coding, or smart monitoring features are increasingly adopted to support asset management and branding.

5. Installation and Maintenance Best Practices

Proper installation is just as important as product selection. Industrial manhole covers must be installed on reinforced concrete foundations, ensuring even load distribution and long-term stability. Incorrect installation can lead to rocking, cracking, or premature failure, even with high-quality covers.

Routine inspection and maintenance extend service life and reduce safety risks. Facility managers should regularly check for surface wear, frame alignment, and corrosion. Replacing worn gaskets and cleaning debris from frames can significantly improve performance and prevent accidents in high-traffic factory environments.

6. Future Trends in Industrial Manhole Cover Solutions

As industrial parks evolve toward smart and sustainable infrastructure, manhole cover technology is also advancing. Smart manhole covers equipped with sensors can monitor load stress, movement, and unauthorized access in real time. Sustainable materials and optimized casting processes are helping manufacturers reduce carbon footprints while maintaining performance standards.

In the future, buyers will increasingly prioritize lifecycle cost, digital integration, and environmental compliance when selecting manhole covers for industrial parks and factories. Choosing suppliers with strong R&D capabilities and international project experience will become a key competitive advantage.

Conclusion

Manhole covers for industrial parks and factories are far more than simple access components. They are essential infrastructure elements that support safety, efficiency, and long-term operational stability. By understanding material options, load classifications, design features, and maintenance requirements, buyers can make informed decisions that reduce risk and optimize total cost of ownership.

Investing in high-quality, standards-compliant manhole covers is a strategic choice that protects assets, employees, and production continuity. As industrial infrastructure continues to modernize, selecting reliable and future-ready solutions will remain a critical priority for industrial facility managers worldwide.

FAQ

1. What is the best load rating for industrial manhole covers?

For most industrial parks, EN124 D400 is the minimum recommended rating, while heavy-duty areas may require E600 or F900.

2. Why is ductile iron preferred for industrial applications?

Ductile iron offers superior strength, impact resistance, and fatigue performance, making it ideal for heavy traffic and industrial environments.

3. Are composite manhole covers suitable for factories?

Composite covers can be used in medium-load factory areas but are generally not recommended for heavy vehicle routes.

4. How often should industrial manhole covers be inspected?

Routine inspections are recommended at least once or twice per year, depending on traffic intensity and environmental conditions.

5. Can industrial manhole covers be customized?

Yes, many manufacturers offer customization options including size, logo casting, locking systems, and smart monitoring features.