Ductile iron manhole covers play a crucial role in modern urban infrastructure, serving as protective access points for underground utilities such as drainage systems, sewage networks, telecommunications, and electrical lines. Compared with traditional gray cast iron products, ductile iron manhole covers offer superior mechanical performance, safety, and durability, making them the preferred choice for municipalities, contractors, and infrastructure developers worldwide.

With the rapid expansion of cities, increasing traffic loads, and higher safety requirements, infrastructure components must perform reliably under demanding conditions. Ductile iron manhole covers meet these challenges through advanced material properties, optimized structural design, and compliance with international standards.

1. What Are Ductile Iron Manhole Covers?

Ductile iron manhole covers are manufactured using nodular cast iron, also known as spheroidal graphite iron. Unlike traditional cast iron, where graphite appears in flake form, ductile iron contains graphite in spherical nodules. This microstructural difference significantly improves tensile strength, impact resistance, and ductility.

The manufacturing process involves controlled chemical composition, precise melting techniques, and magnesium treatment to achieve the desired nodular graphite structure. As a result, ductile iron manhole covers combine the strength of steel with the corrosion resistance and casting flexibility of iron. This balance makes them highly suitable for complex shapes, load-bearing designs, and long-term outdoor use.

Because of these material advantages, ductile iron manhole covers are widely used in critical infrastructure projects where safety, reliability, and service life are top priorities.

2. Key Mechanical Features of Ductile Iron Manhole Covers

One of the most important features of ductile iron manhole covers is their outstanding mechanical performance. They exhibit high tensile strength, typically exceeding 420 MPa, along with excellent elongation properties. This combination allows the covers to withstand heavy loads and dynamic stresses without cracking or brittle failure.

Ductile iron also offers superior impact resistance compared to gray cast iron. In real-world applications, this means the cover can endure sudden shocks caused by traffic, temperature fluctuations, or accidental impacts. This feature is especially critical in high-traffic areas such as highways, intersections, and industrial facilities.

Additionally, ductile iron manhole covers provide stable load distribution through well-designed rib structures and reinforced frames. This reduces deformation over time and ensures consistent performance throughout their service life.

3. Safety and Anti-Displacement Design Features

Safety is a primary consideration in the design of ductile iron manhole covers. Modern products incorporate multiple safety-enhancing features, including anti-slip surface patterns, locking mechanisms, and anti-displacement designs. These features help prevent accidents involving pedestrians, cyclists, and vehicles.

Anti-slip textures improve surface friction, reducing the risk of skidding in wet or icy conditions. Locking systems prevent unauthorized opening and theft, which is a growing concern in many urban areas. Anti-displacement structures ensure that the cover remains securely seated within the frame, even under repeated heavy loads or vibrations.

By integrating these safety features, ductile iron manhole covers contribute significantly to urban road safety and public confidence in infrastructure systems.

4. Corrosion Resistance and Environmental Performance

Ductile iron manhole covers are designed to perform reliably in harsh environmental conditions. Although iron-based materials are naturally susceptible to corrosion, modern ductile iron covers are protected with advanced surface treatments such as bitumen coating, epoxy coating, or zinc spraying.

These coatings enhance resistance to moisture, chemicals, road salts, and wastewater exposure. In coastal regions or industrial zones, corrosion-resistant coatings significantly extend the service life of ductile iron manhole covers, reducing replacement frequency and maintenance costs.

From an environmental perspective, ductile iron is a recyclable material, supporting sustainable infrastructure development. At the end of its service life, the material can be reused without significant loss of quality, aligning with circular economy principles.

5. Applications of Ductile Iron Manhole Covers in Urban Infrastructure

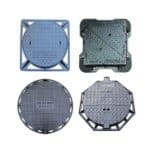

Ductile iron manhole covers are widely used across various urban infrastructure applications. In municipal roads, they provide reliable access to underground utilities while supporting heavy vehicle traffic. Their high load-bearing capacity makes them suitable for installation in highways, arterial roads, and logistics routes.

In residential areas and public spaces, ductile iron manhole covers offer a balance between strength and aesthetics. Custom surface designs and coatings allow them to blend into surrounding pavement while maintaining safety and durability. In industrial parks, their resistance to mechanical stress and chemical exposure ensures stable performance in demanding operational environments.

These diverse applications demonstrate the versatility and adaptability of ductile iron manhole covers in modern city planning.

6. Compliance with International Standards and Quality Assurance

Compliance with international standards is a defining feature of high-quality ductile iron manhole covers. Standards such as EN 124 specify load classes, testing methods, and performance requirements for covers used in different environments, ranging from pedestrian zones to heavy-duty traffic areas.

Manufacturers adhering to these standards implement strict quality control procedures, including material testing, dimensional inspection, and load-bearing verification. This ensures consistent product performance and regulatory acceptance across global markets.

For project owners and engineers, choosing ductile iron manhole covers that meet recognized standards reduces risk, simplifies approvals, and enhances long-term infrastructure reliability.

Conclusion

Ductile iron manhole covers represent a mature and highly reliable solution for modern infrastructure needs. Their superior mechanical strength, safety features, corrosion resistance, and compliance with international standards make them an ideal choice for a wide range of applications.

As cities continue to grow and infrastructure demands increase, the importance of durable, safe, and sustainable components cannot be overstated. By selecting ductile iron manhole covers, municipalities and developers invest in long-term performance, reduced maintenance costs, and improved public safety. These advantages ensure that ductile iron manhole covers will remain a cornerstone of urban infrastructure for years to come.

FAQ: Ductile Iron Manhole Covers

1. What makes ductile iron manhole covers stronger than cast iron?

Ductile iron has a nodular graphite structure that improves tensile strength and impact resistance.

2. Are ductile iron manhole covers suitable for heavy traffic areas?

Yes, they are designed to meet high load classifications for roads and highways.

3. How long do ductile iron manhole covers last?

With proper installation and coating, they can last several decades.

4. Can ductile iron manhole covers be customized?

Yes, they can be customized in size, load class, surface pattern, and coating.

5. Are ductile iron manhole covers environmentally friendly?

Yes, ductile iron is recyclable and supports sustainable infrastructure practices.