Manhole cover and frame systems are critical components of modern urban infrastructure. They provide safe access to underground utilities while ensuring structural integrity, load-bearing capacity, and public safety in roads, sidewalks, and industrial areas.

Although often overlooked, each manhole cover and frame system is engineered with multiple functional components designed to meet specific performance, durability, and safety requirements. Based on practical manufacturing and project experience, this guide explains the basic components of a manhole cover and frame system and how they work together in real-world applications.

What Is a Manhole Cover and Frame System?

A manhole cover and frame system consists of a removable cover and a fixed supporting frame installed at ground level over underground chambers. These systems allow access to utilities such as:

- Sewer and drainage systems

- Telecommunications and electrical networks

- Water supply and gas pipelines

- Industrial inspection chambers

The design must balance accessibility, load resistance, durability, and safety under continuous traffic and environmental exposure.

Why Understanding Manhole Cover Components Matters

Understanding the basic components of a manhole cover and frame system is essential for:

- Proper product selection for different load classes

- Ensuring compliance with EN, ASTM, or AASHTO standards

- Reducing long-term maintenance costs

- Improving safety for pedestrians and vehicles

Each component plays a specific role in overall system performance.

Core Components of a Manhole Cover and Frame System

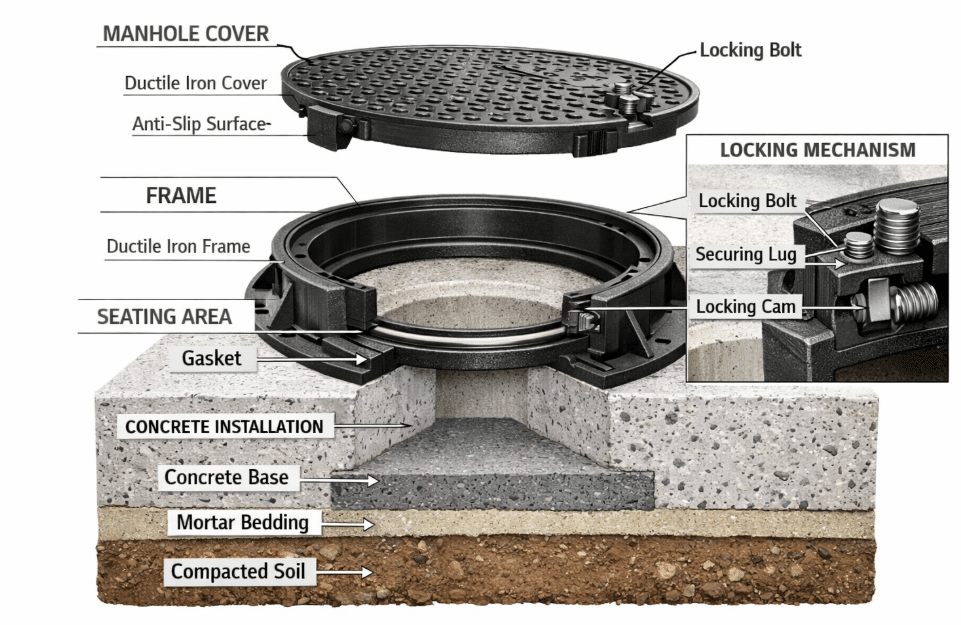

Manhole Cover

The manhole cover is the visible and removable top component. Its primary function is to seal the opening while allowing periodic access for inspection and maintenance.

Key features include:

- Load-bearing surface

- Anti-slip texture

- Secure seating within the frame

Covers are designed in different shapes, most commonly round or square, depending on application requirements.

Manhole Frame

The manhole frame is a fixed structural component embedded into concrete or pavement. It supports the cover and transfers loads from traffic to the surrounding structure.

Functions of the frame include:

- Providing a stable seating surface for the cover

- Preventing lateral movement

- Maintaining correct elevation with road or pavement level

Frame quality directly affects system longevity and safety.

Seating Area and Contact Surface

The seating area is where the manhole cover rests on the frame. This interface is critical for load distribution and noise control.

Well-designed seating areas help to:

- Prevent rocking or displacement

- Reduce vibration under traffic

- Minimize wear on both cover and frame

Some systems include machined seating surfaces or elastomer inserts for improved performance.

Locking and Fixing Mechanisms

Locking systems are used to secure the manhole cover to the frame, especially in high-traffic or public-access areas.

Common locking mechanisms include:

- Bolt-down systems

- Hinged covers with safety locks

- Key-operated locking devices

These features enhance safety by preventing unauthorized access and accidental displacement.

Hinges (Optional Component)

Hinges are optional but commonly used in heavy-duty or safety-critical applications.

Benefits of hinged manhole covers include:

- Reduced risk of cover removal accidents

- Controlled opening and closing

- Improved safety for maintenance personnel

Hinges are often required in industrial zones or areas with high pedestrian traffic.

Gaskets and Sealing Elements

Gaskets are installed between the cover and frame to improve sealing and performance.

Their functions include:

- Preventing water ingress

- Reducing noise caused by traffic vibration

- Improving overall stability

Elastomer or rubber gaskets are commonly used in high-quality systems.

Ventilation and Drainage Features

Some manhole covers include integrated ventilation or drainage openings.

These features allow:

- Gas release from underground chambers

- Water drainage to prevent pooling

- Pressure equalization

Ventilated designs are commonly used in sewer and utility networks.

Material Selection for Manhole Cover Components

Ductile Iron

Ductile iron is widely used due to its:

- High strength and impact resistance

- Excellent load-bearing capacity

- Long service life

It is suitable for roads, highways, and industrial areas.

Cast Iron

Cast iron offers good compressive strength and is commonly used in low-traffic applications such as sidewalks or green areas.

Composite Materials

Composite manhole covers are increasingly used for:

- Lightweight handling

- Corrosion resistance

- Electrical insulation

They are ideal for telecom and utility installations.

Steel and Stainless Steel

Steel components are used in special industrial or architectural applications requiring high strength or corrosion resistance.

Load Classes and Performance Requirements

Manhole cover and frame systems are designed according to load classification standards such as:

- EN 124 (Europe)

- AASHTO M306 (North America)

Load classes range from pedestrian areas to heavy-duty traffic zones, ensuring the system can withstand expected loads safely.

Anti-Slip Surface Design

Surface texture is a critical safety feature.

Anti-slip designs may include:

- Raised patterns

- Textured finishes

- Special coatings

These features reduce the risk of slipping in wet or icy conditions.

Installation Interface with Pavement

Proper integration with surrounding pavement is essential.

Key considerations include:

- Correct frame height alignment

- Secure anchoring in concrete

- Even load transfer

Poor installation can compromise even high-quality components.

Durability and Environmental Resistance

Manhole cover components must resist:

- Corrosion

- Freeze-thaw cycles

- Chemical exposure

Material choice and protective coatings play a major role in long-term durability.

Maintenance Considerations

Well-designed manhole cover and frame systems reduce maintenance requirements.

Maintenance typically involves:

- Visual inspection for wear or damage

- Checking seating surfaces

- Ensuring locking mechanisms function properly

Routine inspection extends service life and maintains safety.

Common Design Variations

Manhole cover systems may vary by:

- Shape (round, square, rectangular)

- Frame depth and profile

- Locking and hinge options

Design variations allow customization for specific project needs.

Real-World Application Experience

In municipal and infrastructure projects, systems with properly engineered frames, stable seating areas, and secure locking mechanisms consistently perform better under long-term traffic loads.

Experience shows that investing in quality components reduces lifecycle costs and safety incidents.

How to Choose the Right Manhole Cover and Frame System

When selecting a system, consider:

- Load class requirements

- Environmental conditions

- Installation environment

- Compliance with local standards

Working with experienced manufacturers ensures proper design and material selection.

Conclusion

A manhole cover and frame system is more than a simple access point. Each component—from the cover and frame to seating surfaces and locking mechanisms—plays a vital role in safety, durability, and performance.

Understanding these basic components helps engineers, contractors, and project owners make informed decisions and ensure reliable infrastructure systems.